THE ESCO APS Air Powered Boiler Saws and accessories are a must-have for anyone who has to cut through boiler tubes, pendant membranes or concrete pilings.

These professional, air-powered boiler saws and accessories can cut through just about any material in the industry. They’re perfect for cutting pendant tubes or concrete pilings that are too hard to penetrate with traditional methods alone!

Our ESCO products will help ensure your job gets done right, quickly so it won’t be too much trouble for our customers in need of this service..

Some of the most common plants that seek to cut or modify pipes are alumina, power station and sugar mills.

Other industries include fertiliser production for agriculture purposes and paper manufacturing.

Lastly there’s gas plant construction specifically designed around delivering fuel safely through narrowest diameter tubes without allowing any leaks.

- ESCO’s Millhog Air Powered Boiler Saw is a versatile solution that can be used to cut boiler tube panels, boiler tube membranes, and pendant tubes.

- The saw can also be used to squarely cut pipe, concrete pilings, and storage tanks.

- ESCO’s APS Air Powered Boiler Saw is a versatile solution that can be used to cut boiler tube panels, boiler tube membranes, and pendant tubes.

- ESCO offers a variety of saws and accessories that can be used to meet the needs of any plant seeking solutions for cutting and modifying pipes and piping.

Boilermaker Tough and Field Proven

With the MILLHOG® Air Powered boiler tube panel saw, you can cut all your alloys in one go with ease.

The EscoTrack system securely attaches to any type of steel – even ones that are hard or irregularly shaped.

Simply attach this powerful tool onto a section using weld tabs and make your horizontal cuts; then simply rotate it 90 degrees before reattaching foryour vertical cuts.

The powerful motor and proprietary reinforced fiberglass abrasive blade cut all alloy efficiently, making both horizontal or vertical cuts possible after completing one simple procedure!

For even faster membrane removal, you can use the membrane removal bracket and available 0.250” (6.35 mm) or 0.375” (9.53 mm) membrane removal blades.

Combining a MILLHOG® tube beveling tool equiped with a membrane or membrane and overlay (cladding) removal head, the tube end prep and its outside diameter are quickly and economically prepared for welding.

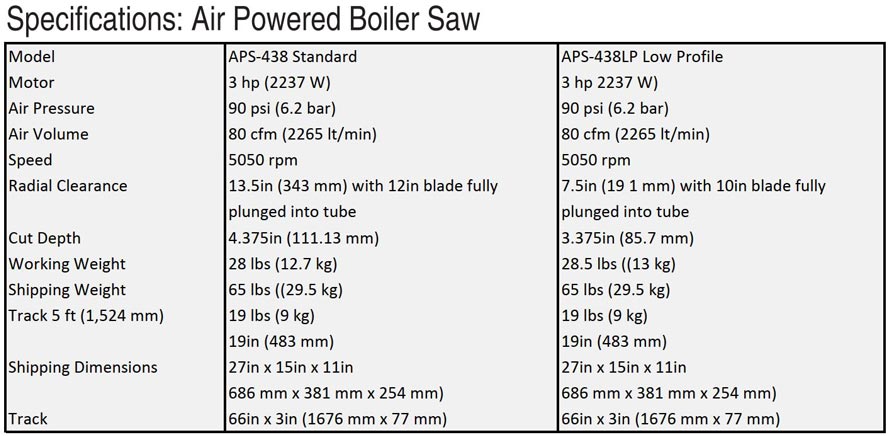

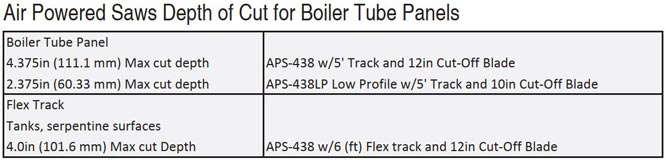

APS-438 Standard Boiler Tube Panel Saw

APS-438LP Low Profile Boiler Tube Panel Saw

Membrane Bracket

Chain Mount Tab & Track Connector

Quick Clamp

Vertical Track Alignment

Cut-Off Blades and Membrane Removal Blades