Ventil Transportable Workshops

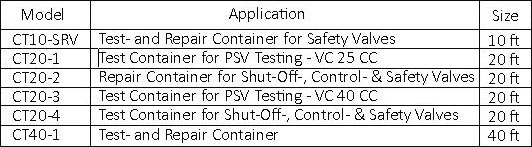

Model: CT

Fully equipped test and repair facilities for on-site overhaul and testing of Shut-off valves, Safety valves and Control valves. The 10, 20 or 40 ft Containers feature all necessary tools and equipment for the standard recondition procedure, but can also be equipped for your specific application and environment / climate conditions.

For off-shore applications, the new fabricated container is certified according to DNV 2.7 / EN 12079 and can optionally be prepared for the use of explosive (ATEX) atmospheres.

BUY/RENT & FREE TRAINING

SPEC SHEETS

| COMPLETE VENTIL PRODUCT RANGE | DOWNLOAD THE BROCHURE |